Explore various customer deployment scenarios designed for our Stockholm 4 South site, with its flexible design and preparation for high density and liquid cooling. Here, you’ll find three distinct examples, each highlighting a different approach to effective cooling:

Each example provides detailed insights and practical layouts to help you envision the best cooling strategy for your needs.

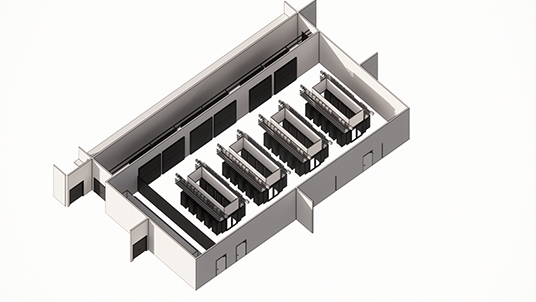

How this deployment could look like in this scenario.

Alternative configurations can be accommodated to meet varying needs, including setups designed to support high-performance computing clusters used in leading-edge AI deployments. Please note that this is just one example; for different deployments or specific setups, we offer flexibility and welcome you to contact us to discuss your needs in more detail.

liquid cooling, totaling 3.6 MW

two sets of two 63A 3-phase PDUs

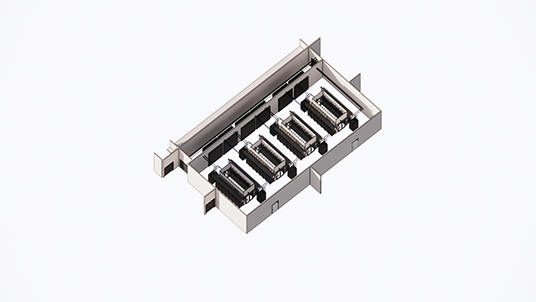

How this deployment could look like in this scenario.

Alternative configurations can be accommodated to meet varying needs, including setups designed to support high-performance computing clusters used in leading-edge AI deployments. Please note that this is just one example; for different deployments or specific setups, we offer flexibility and welcome you to contact us to discuss your needs in more detail.

multiple immersion cooling systems

0.5 MW (4 tanks per system)

equipped tanks having 52U each

used for air cooled systems

two sets of three 63A 3-phase PDUs

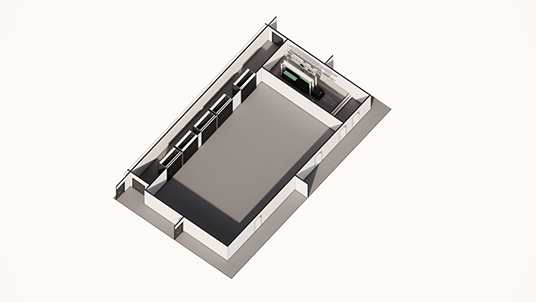

How this deployment could look like in this scenario.

CONTACT ME

CONTACT ME  NEWSLETTER

NEWSLETTER  SITE TOUR

SITE TOUR